Scandium provides a gateway to innovation across a series of cutting-edge industries. It can produce breakthroughs in aerospace technology, helps manufacturers delve into the future of 3D printing, optimizes energy efficiency through innovative heat exchanger engineering, powers the next evolution of high-voltage conductors, and transforms solid oxide fuel cells as a sustainable power source.

Through Element North 21’s scandium operations, we can help industry leaders navigate the frontiers of technology and reshape the landscape of commercial possibilities.

Aerospace

Let’s fly to the next level

Through a microalloying process, scandium can help increase the strength and the weldability of an aluminium airframe while generating significant fuel savings and emission reductions for airline operators. Aluminium-scandium alloys have the potential to lower direct manufacturing costs and maximize manufacturing and repair capacity.

By supplying a sustainable and reliable source of scandium, Rio Tinto is persuading today’s aerospace firms, manufacturers, and engineers to test out aluminium-scandium alloys and make it their metal of choice.

Aluminium-scandium alloys for aerospace engineering and manufacturing

Improved weldability

Adding a small percentage of scandium to an aircraft’s aluminium-alloy components is proven to reduce sensitivity to hot cracking during the welding process. Indeed, due to its high recrystallization temperature, the aluminium alloys maintain their properties.

Weight reduction and fuel savings

Scandium allows for aircrafts to have a thinner fuselage, helping in turn maximize fuel efficiency.

Corrosion resistance and thermal stability

Airframes made from aluminium-scandium alloys are more resistant to corrosion and ensure thermal stability when exposed to higher temperatures. For airline carriers, it means owning more durable aircrafts that require fewer repairs in the long run.

3D Printing

Printing metals with enhanced mechanical performance

As more businesses look to reproduce spare metal parts and shapes with enhanced mechanical properties, 3D alloy printing technology has recently seen a steady increase in development. With the introduction of aluminium-scandium alloys to the additive manufacturing process, 3D metal printing enters a new and exciting phase.

With aluminium-scandium powders, you can produce replacement parts that would offer higher mechanical properties (increased strength and heat resistance) for the same geometry.

As a result, you are 3D printing higher-grade alloys at a rapid pace using a cost-efficient production process that involves less waste material.

High-purity scandium for high temperature 3D applications

Complex castings

When it comes to producing unusual and complex aluminium shapes/parts through 3D printing, aluminium-scandium alloys allow you to create a variety of geometric forms (including hollow spaces and honeycombs) that maintain microstructural stability while minimizing post-processing steps.

Cost efficiency

It can cost less to produce your aluminium parts when you use scandium in the manufacturing process reducing the need for additional heat treatment and quenching steps.

Fast and reliable

With scandium, your aluminium parts produced through 3D printing increase in strength and are less prone to defects, allowing you in turn to decrease your production lead time.

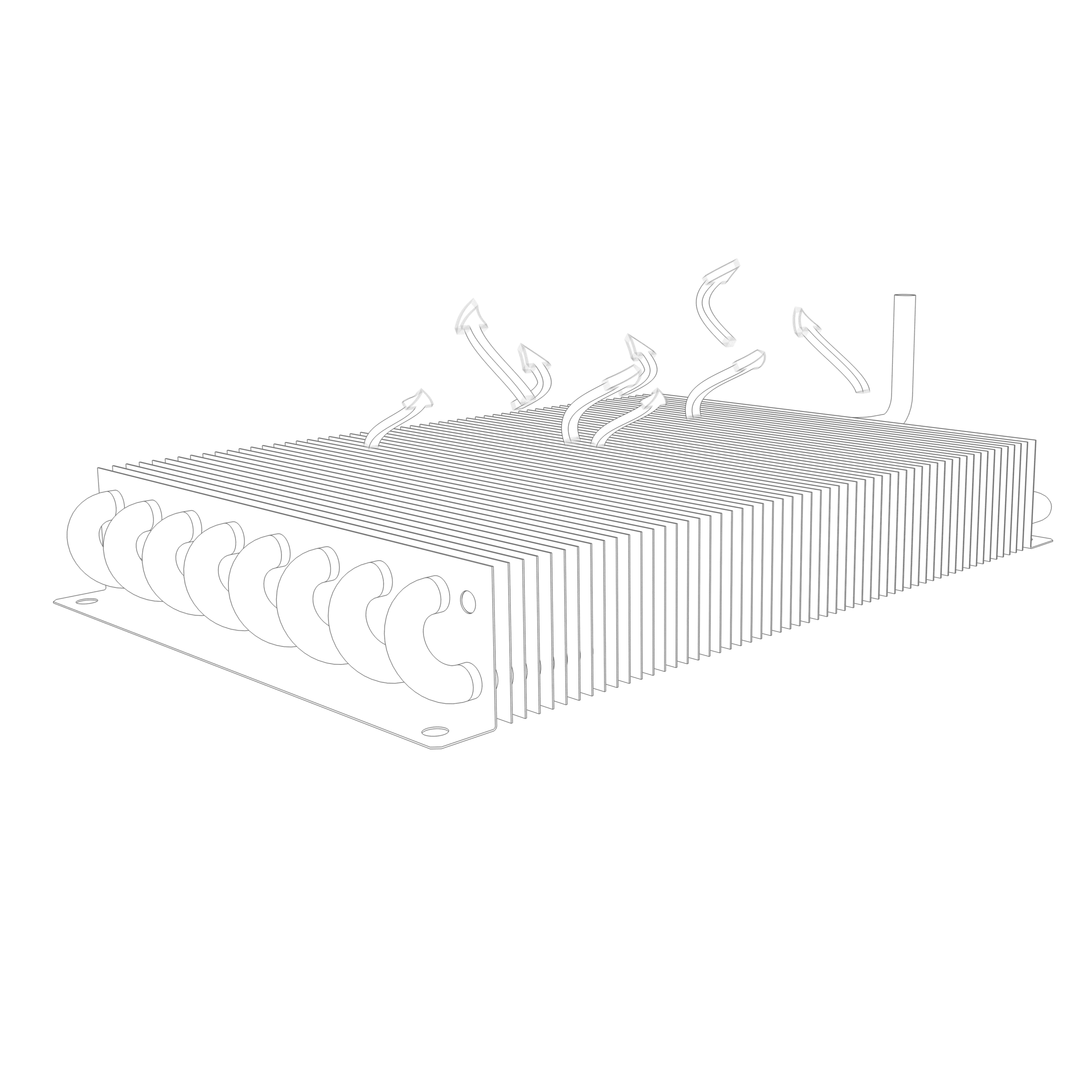

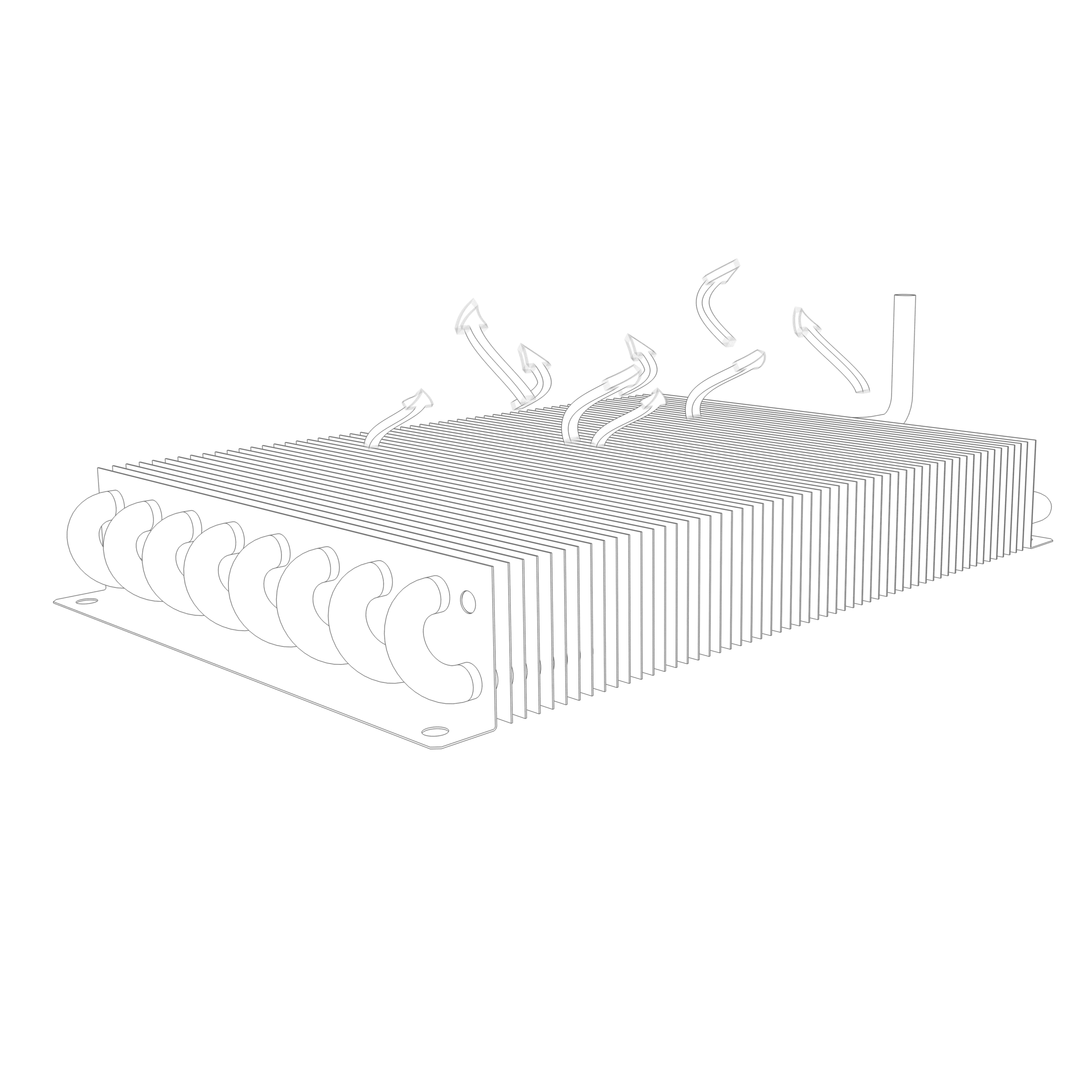

Heat Exchangers

Maximize heat with the help of scandium

With aluminium-scandium, your manufacturing tubes with a higher strength, are lighter in weight and have a greater resistance to temperature-induced cracking.

Aluminium-scandium is the key element to stand out from the competition. It provides superior thermal conductivity, increased mechanical resistance allowing you to reduce the size of the tubes and the weight of the unit, and greater burst pressure resistance to help you avoid costly production line defects.

Aluminium-scandium in heat exchanger manufacturing processes

Excellent thermal conductivity

Manufacturing industrial heat exchangers using aluminium-scandium alloys potentially requires less force during the extrusion process and produces a unit with a superior thermal exchange capacity.

Greater resistance

Heat exchangers designed with aluminium-scandium alloys turn out to be more mechanically resistant (stronger, resistant to heat effects like cracking), allowing you in turn to reduce the tube thickness or incrase the temperature or pressure used in operation.

Increased burst pressure resistance

In some cases, aluminium-scandium can improve the burst pressure resistance of your heat exchanger by up to 80%.

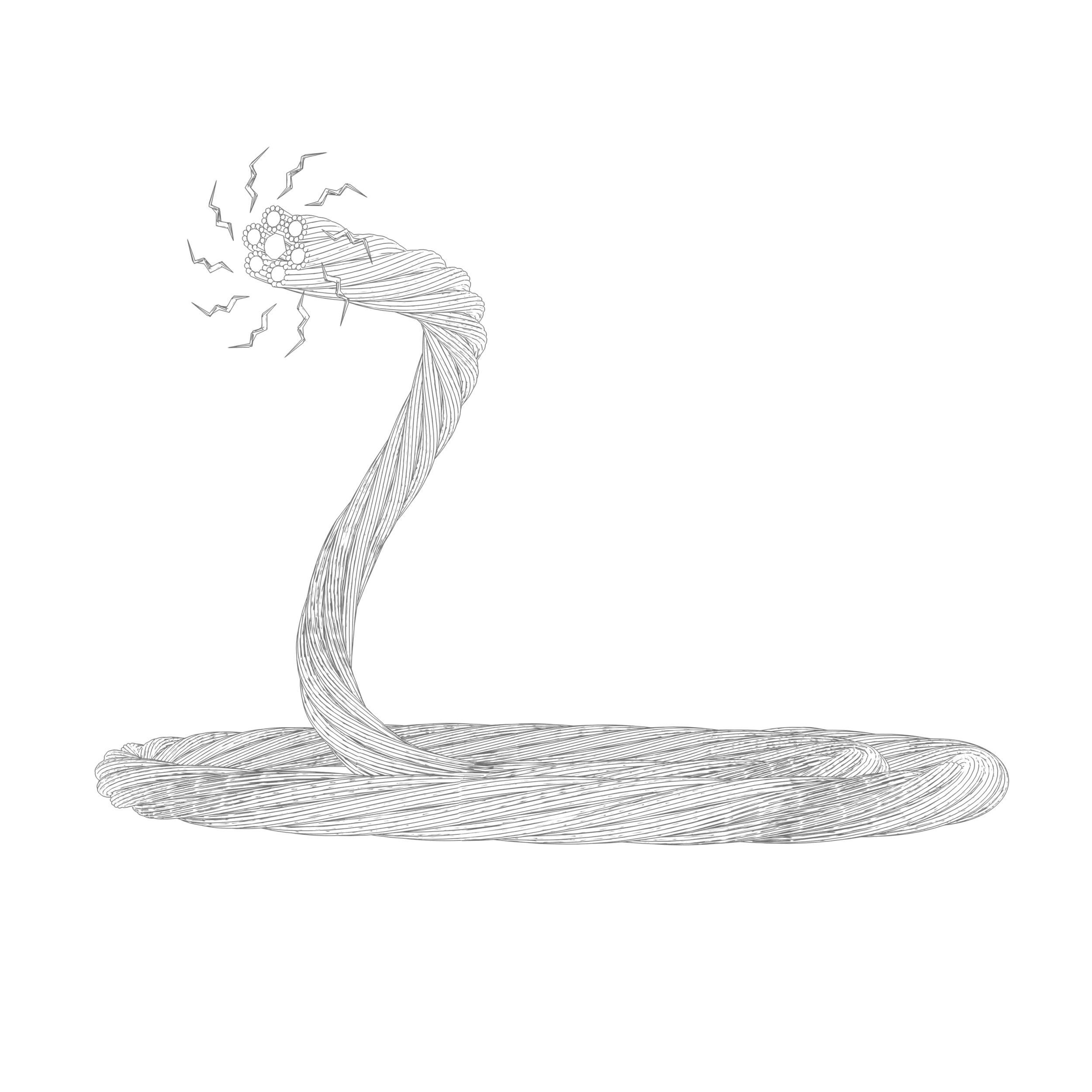

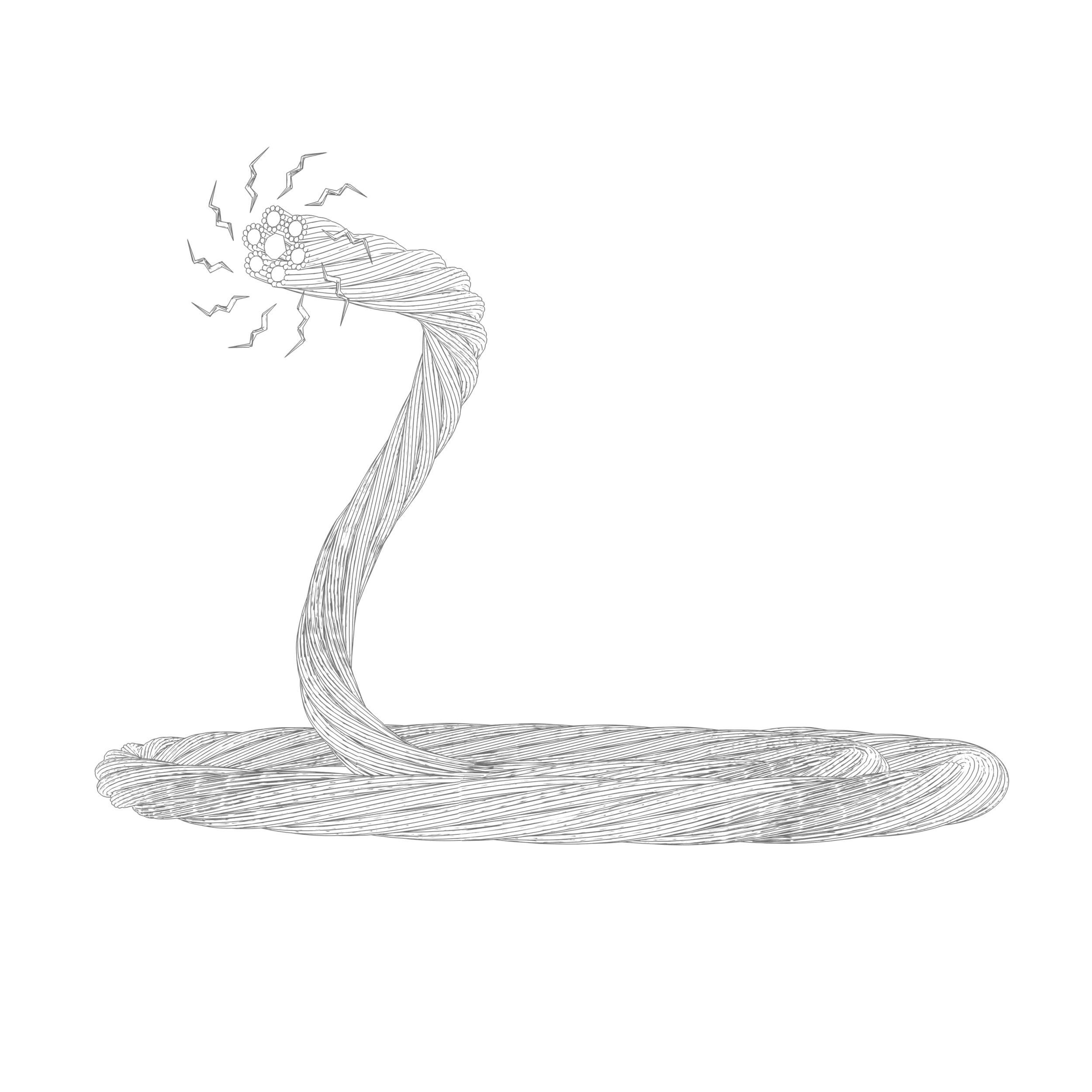

High-Voltage Conductors

Ensuring efficient electrical conductivity

Scandium can have significant positive impacts to the power industry. Cables can be made lighter, stronger and with higher conductivity and electrical conductors have higher heat resistance.

Less weight, more power, better resistance to handle high-voltage peaks: Who knew all it took was a touch of scandium to push the electric industry to the next level?

Exploiting the aluminium-scandium advantage in high-voltage conductors

Reduced weight and higher strength

Scandium alloy cables can have less designed-in sag, translating to the need for fewer towers.

Greater mechanical strength and increased conductivity

Electrical conductors manufactured using scandium are more resistant to high temperatures exposure, which allows for greater electrical currents to be used without affecting the mechanical properties of the aluminium.

Game changer

Aluminium-scandium allows cables used in electric power transmission to efficiently handle larger currents, especially during peak times.

Solid Oxide Fuel Cells

Scandium oxide stabilized SOFCs: A sustainable power source for the future

Fuel cells may have been used as an electrical power supply source for various sectors for more than 100 years, but the current solid oxide fuel cell design stands out from the pack. SOFCs are more energy efficient, adapted to different fuel sources, contain fewer exotic metal components in their structure and have a minimal impact on the environment.

SOFCs operate at temperatures of approximately 1,000 ⁰C and use a hard ceramic material as a solid electrolyte (typically zirconia). Traditionally, yttria has been used as a stabilizing agent for the solid electrolyte, but recent SOFC designs have demonstrated that scandium oxide is a superior stabilizing agent and a better ionic electrical conductor than yttrium.

BOTTOM LINE: Scandium helps the SOFC’s electrolyte to conduct at lower temperatures (between 750 and 800⁰C). It’s also a superior, electrolyte stabilising agent and helps improve conductivity which leads to lower operating temperatures, dramatically increasing operating life cycles by 3 to 5 times.

Increased service life, greater power outputs and cost savings: Scandium oxide stabilized SOFCs are today’s leading choice for the grid-supplied electrical power sector.

Using scandium oxide to enhance solid oxide fuel cells (SOFC)

Stabilizing agent alternative

Scandium oxide can substitute for yttria (yttrium oxide) as a stabilizing agent for the solid electrolyte located inside the fuel cell.

Increased conductivity

When compared to yttrium oxide, scandium oxide helps increase the electrolyte conductivity in SOFCs by more than 300%.

Extended lifespan

Scandium oxide allows conductivity to occur at lower temperatures in SOFCs, in turn extending the lifespan of its components and maximizing its power density.